Looking for an extra performance edge? Bonehead Performance Coatings offers specialized high-performance ceramic coating solutions engineered for advanced thermal control, friction reduction, and heat dissipation.

These ceramic-based coatings are designed for high-temperature, high-stress environments and are commonly used in performance automotive, powersports, heavy equipment, and racing applications.

We offer three primary high-performance ceramic coating systems: Thermal Barrier Coatings, Dry Film Lubricant Coatings, and Heat Dissipation Coatings.

Thermal Barrier Coatings

Thermal barrier coatings significantly reduce heat transfer from components operating at elevated temperatures. These coatings are used extensively in performance-driven applications where controlling heat improves efficiency, durability, and reliability.

Thermal barrier coatings can alter heat transfer by up to 15%, depending on the application, while also providing corrosion resistance and long-term durability.

Recommended Uses:

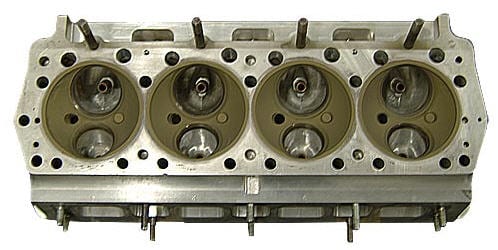

- Piston domes

- Combustion chambers

- Valve faces

- Exhaust systems and components

Dry Film Lubricant Coatings

Dry film lubricant coatings are designed to create a permanent lubricated surface that reduces friction, wear, galling, and seizing of components. These coatings become an intrinsic part of the component rather than a surface-applied layer.

Dry-film lubricant coatings enable components to operate with extremely low friction, reducing surface-to-surface contact and extending component life.

Recommended Uses:

- Piston skirts

- Cylinder walls

- Crankshafts and camshafts

- Bearings and gears

- Valve stems and rocker pivots

Heat Dissipation Coatings

Heat-dissipation coatings are engineered to transfer heat away from a substrate, improving the efficiency, performance, and longevity of coated parts. These ceramic-bonded, thermally conductive coatings also provide corrosion protection and resistance to chemical and solvent attack.

Heat-dissipation coatings are widely used in transportation, electronics, and high-performance applications to reduce residual heat buildup.

Recommended Uses:

- Radiators

- Brake drums

- Oil coolers

- Differentials

- Transmission cases

- Lighting equipment

- Heat exchangers

- Transmission coolers

- Air conditioning condensers

Transfer Grey (C-187)

Transfer Grey is formulated to increase thermal transfer from a surface to a free-flowing air environment. When applied to metal substrates, this coating has been proven to increase thermal transfer by up to 35–40% compared to uncoated metal.

Improved thermal transfer allows components to operate at lower temperatures, increasing efficiency and extending component life.

Arctic Black (P-202)

Arctic Black is a resin-bonded, thermally conductive solid film lubricant designed to protect, lubricate, and radiate heat from metal surfaces. It provides excellent corrosion protection, chemical resistance, and high-temperature lubrication.

Arctic Black has been shown to increase heat transfer by approximately 10–15% compared to uncoated metal substrates. It features a darker black finish, while Transfer Grey offers a dark gray appearance.

Turnaround Time & Shipping

Typical turnaround time for high-performance ceramic coating projects averages one to two weeks once parts arrive at our facility. Actual turnaround time may vary depending on part condition and workload.

We accept parts shipped from across the United States. Transit time is separate from coating time, and all parts must be fully disassembled prior to shipment.

View shipping and preparation requirements

Request an Estimate

If your project requires high-performance ceramic coatings, request an estimate to discuss coating selection, performance requirements, and turnaround time.