Vapor Honing (Wet Blasting) for Precision Surface Finishing

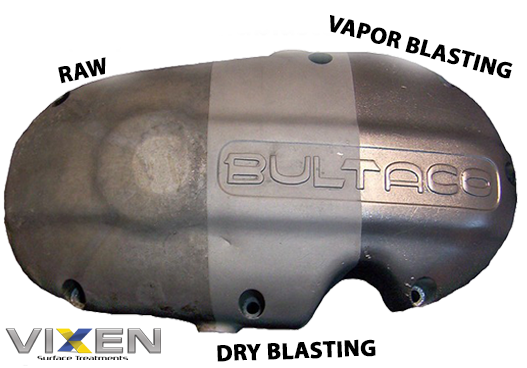

Vapor honing, also known as wet blasting, vapor blasting, slurry blasting, or liquid honing, is rapidly becoming the preferred surface preparation method for applications requiring the highest quality surface finish.

Unlike dry blasting methods, vapor honing uses water-borne abrasive media to clean and finish components in a controlled, dust-free environment.

What Is Vapor Honing?

Vapor honing differs from traditional dry blasting because the finish is achieved by the controlled flow of abrasive suspended in water rather than direct media impact. The water acts as a lubricant and cushioning agent between the media and the component surface.

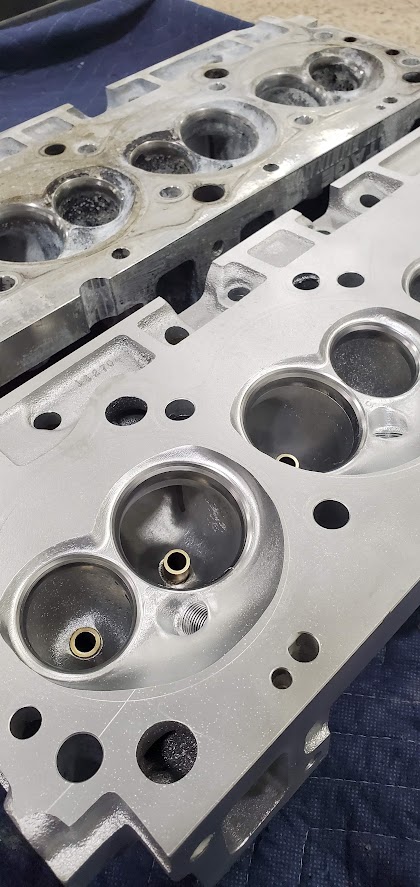

This process reduces media ricochet, changes the impact angle, and creates a lapping action across the surface. The result is a uniform satin or lightly polished finish without aggressive material removal.

Because vapor honing is dust-free, it is safer for delicate components and produces consistent, repeatable results.

The Vapor Honing Process

Unlike dry blasting, vapor honing does not allow abrasive media to become impregnated into the component surface. The process also eliminates airborne dust created by media breakdown.

A specially designed glandless polyurethane pump continuously agitates water and abrasive into a slurry, which is then pumped to the blast gun. Compressed air is added at the blast nozzle to accelerate the slurry and achieve effective cleaning.

After contacting the component, the slurry drains back into a sump, creating a closed-loop, recirculating system. Broken-down media is removed through an overflow system and filtered via sedimentation, ensuring consistent performance and media reuse.

Benefits of Vapor Honing

- Produces a uniform satin or polished surface finish

- Less aggressive than dry blasting methods

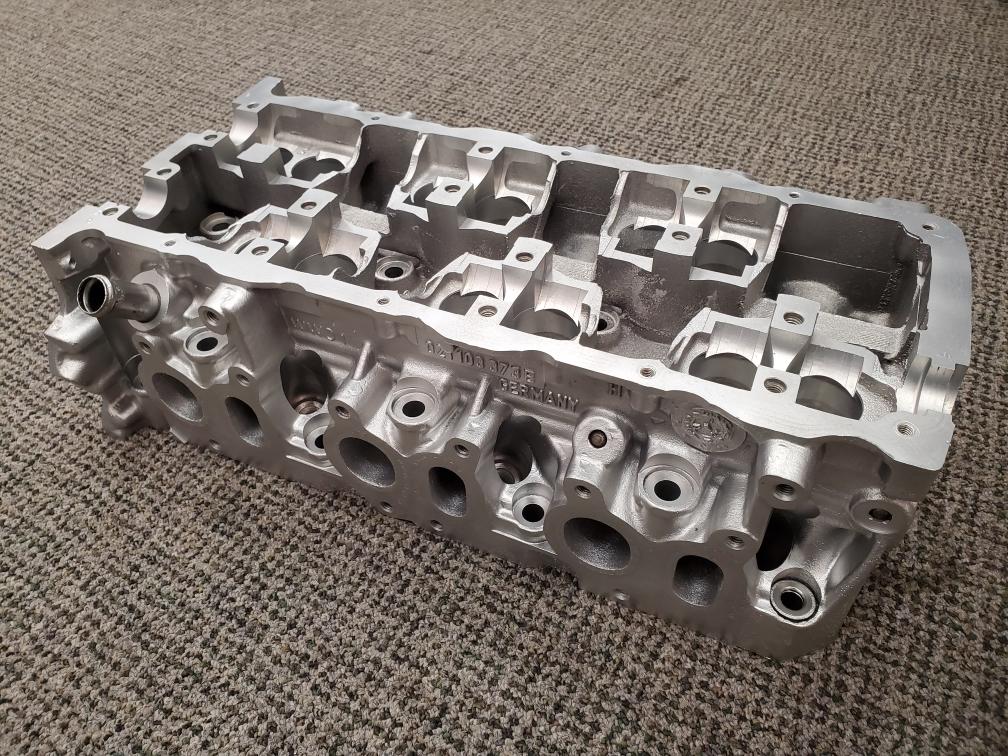

- Preserves part geometry and fine details

- Dust-free and environmentally controlled process

- Prevents media embedding in component surfaces

Vapor Honing Applications

Vapor honing is well-suited for both cleaning and surface finishing applications, including:

- Degreasing and surface finishing of components

- Cleaning of dies and molds

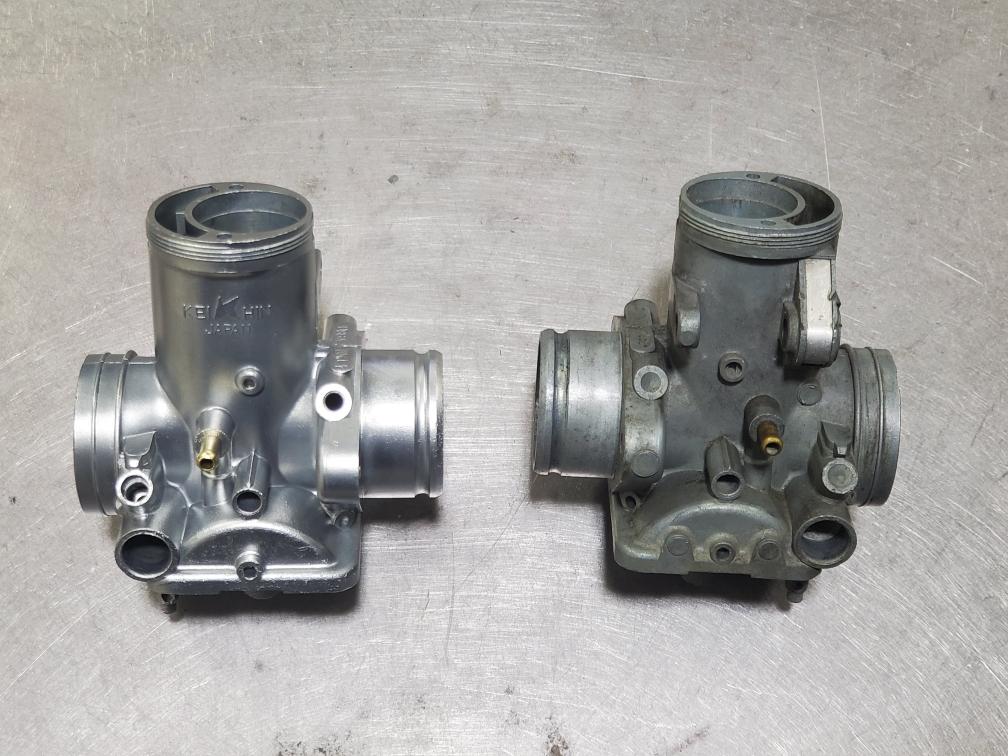

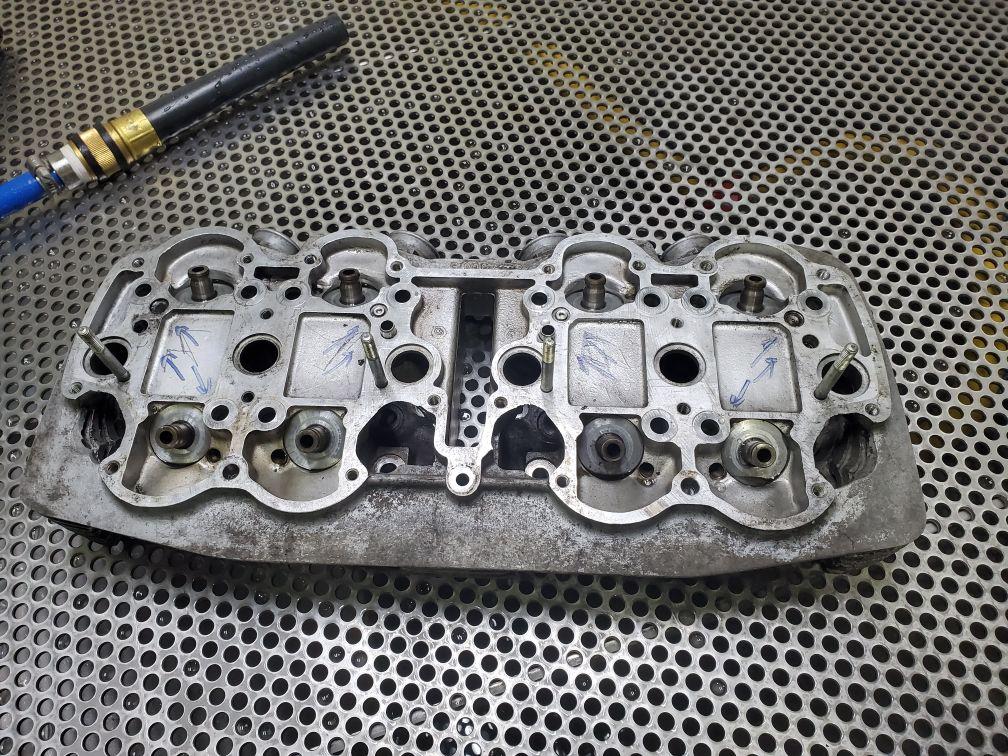

- Removal of paint, rust, scale, carbon, and deposits

- Surface preparation prior to bonding, painting, or coating

- Satin finishing of stainless steel, brass, and specialty materials

- Deburring CNC-machined parts

Industries & Use Cases

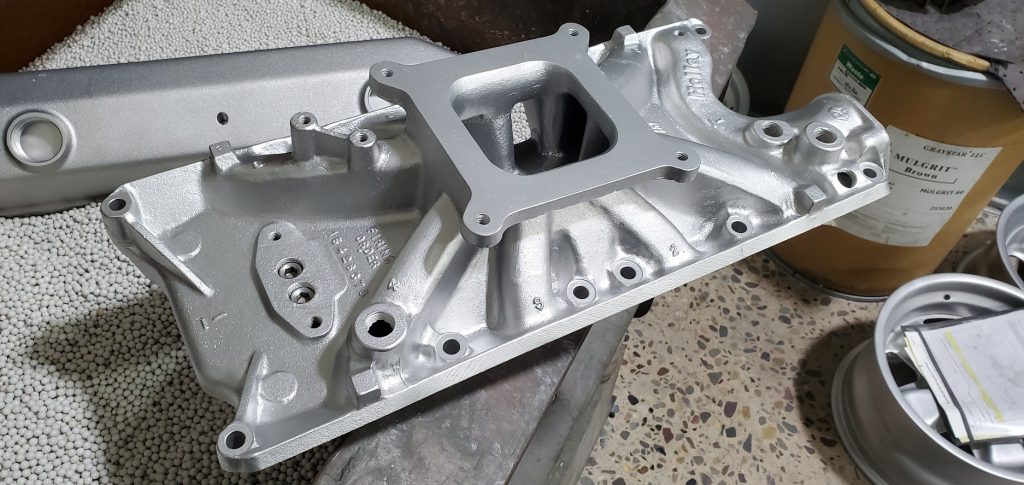

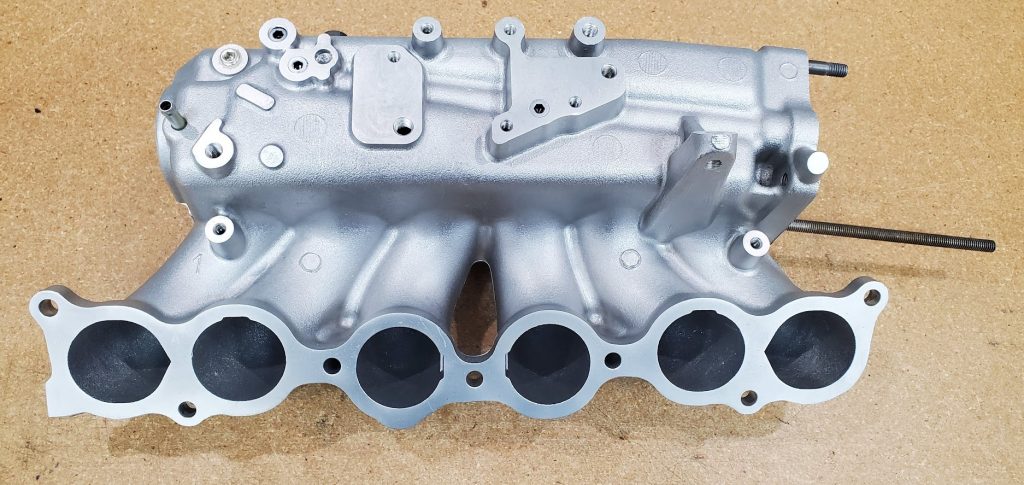

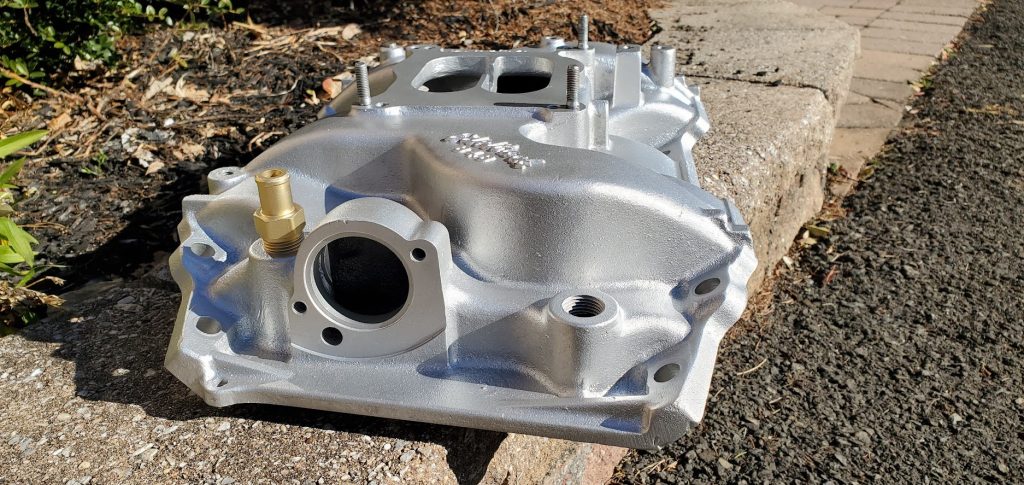

- Automotive restoration

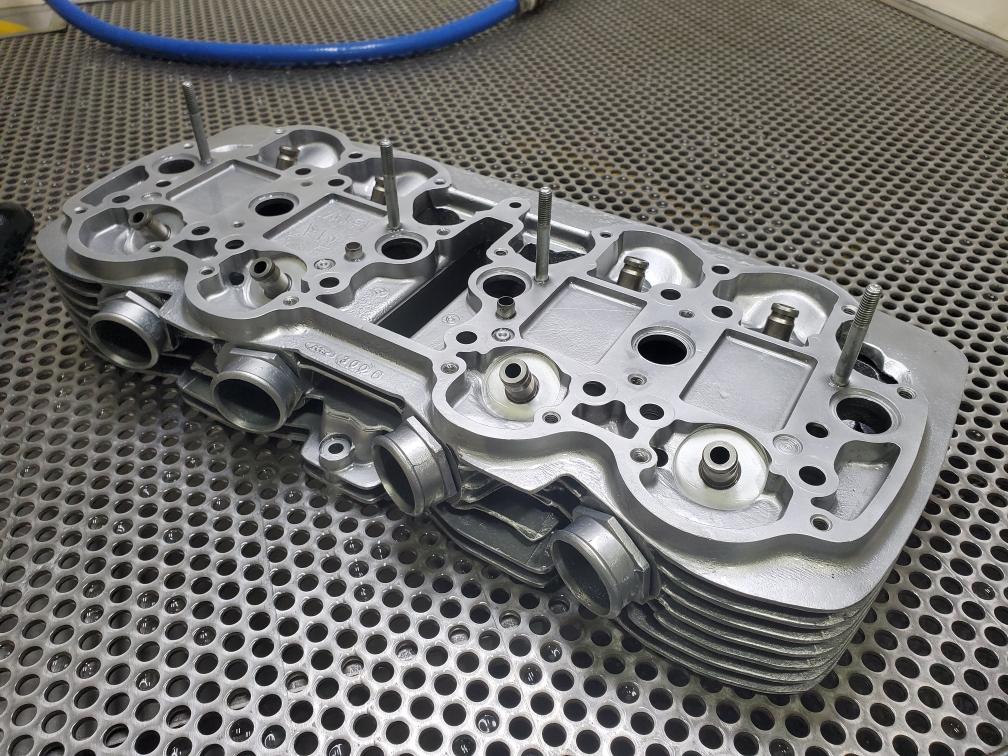

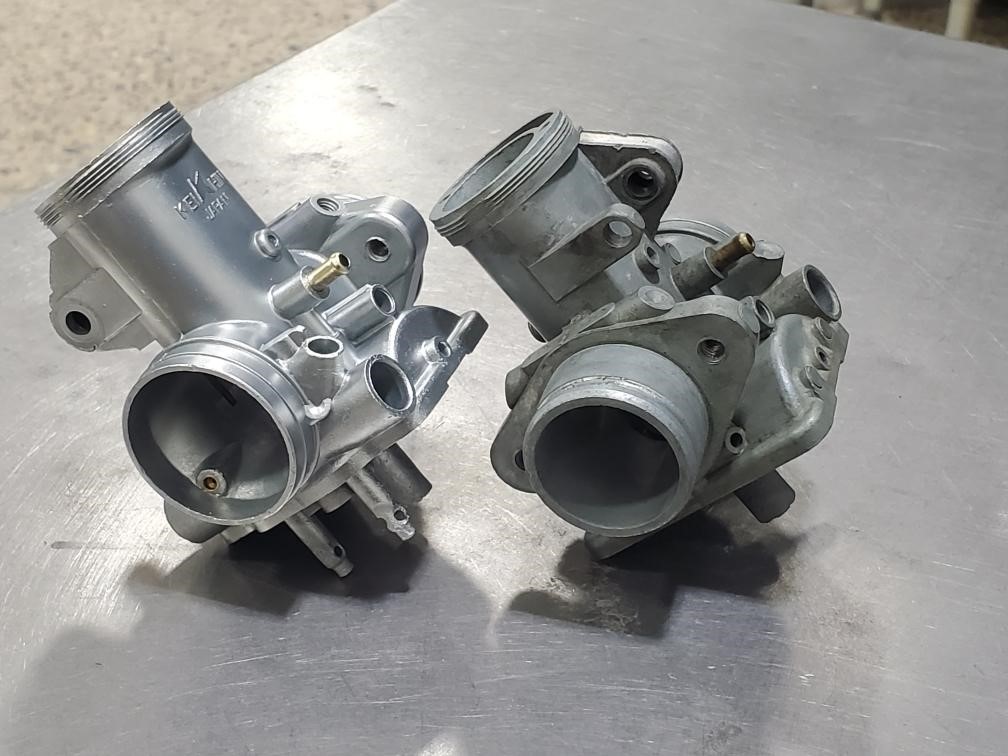

- Motorcycle engine components

- High-performance engine building

- Automotive part remanufacturing

- Diesel engine rebuilding

- Deburring precision-machined parts

- Tool and die applications

- Cutting tools and specialty components

Vapor Honing for Coating Applications

Vapor honing is commonly used as a preparation step prior to powder coating or ceramic coating, where surface appearance and dimensional integrity are critical.

View powder coating services

View ceramic coating services

Turnaround Time & Shipping

Turnaround time for vapor honing depends on part condition and workload. In many cases, vapor honing is completed as part of the overall coating preparation process.

We accept parts shipped from across the United States. All parts must be fully disassembled prior to shipment.

View shipping and preparation requirements

Request an Estimate

If your project requires precision surface finishing, request an estimate to determine whether vapor honing is the appropriate preparation method.