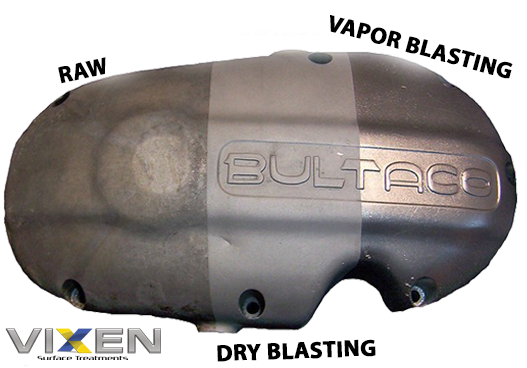

Vapor Honing aka: Wet Blasting!

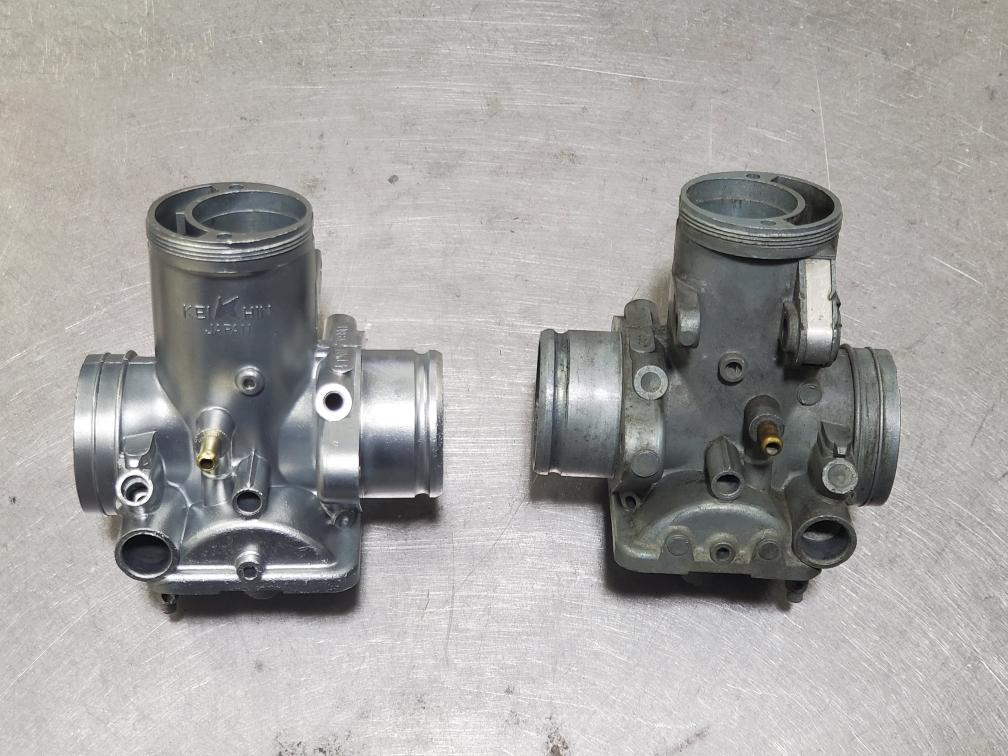

Wet blasting is rapidly becoming the number one choice for applications requiring the highest quality of surface finish.

Wet blasting can also be known as vapor blasting, slurry blasting and liquid honing. There are numerous reasons why wet blasting is becoming more favorable over dry blasting and this is primarily because of its two key features; firstly, the finish is achieved by the flow of water borne abrasive – not by impact, and secondly because it is a dust-free process.

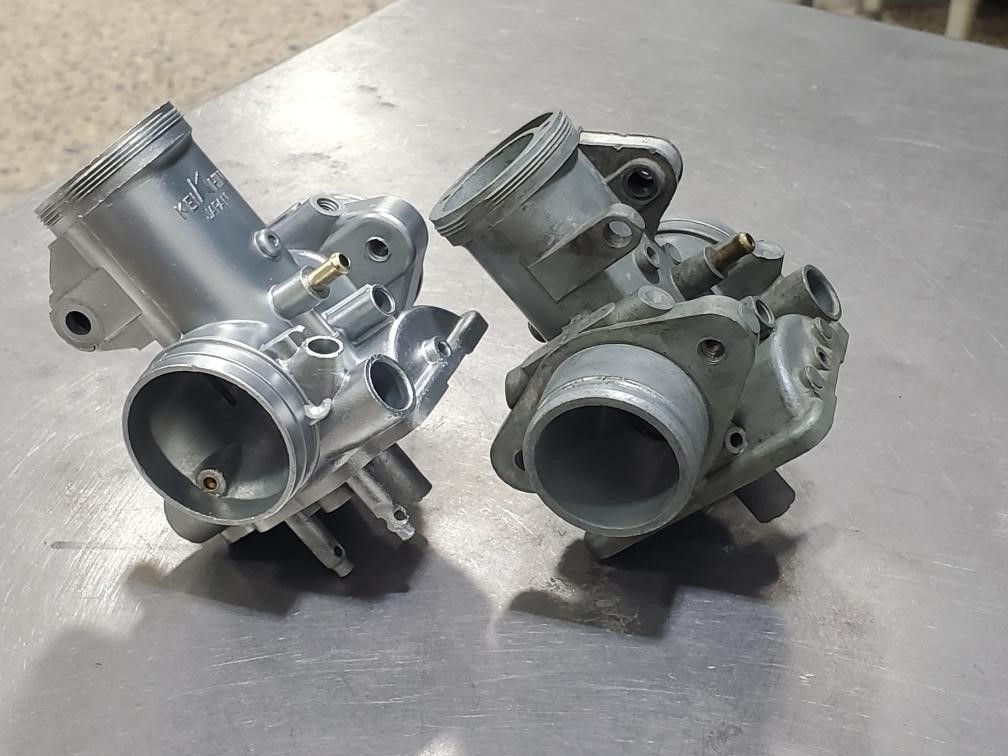

Wet blasting is a less aggressive form of blasting in comparison to dry blasting, working just as effectively. The ricochet of media is reduced due to the cushioning effect created from the water acting as a lubricant between the media and the component surface. As a result, the angle of the media is changed, producing a lapping effect travelling across the surface, resulting in an even satin/ polished finish.

The Process:

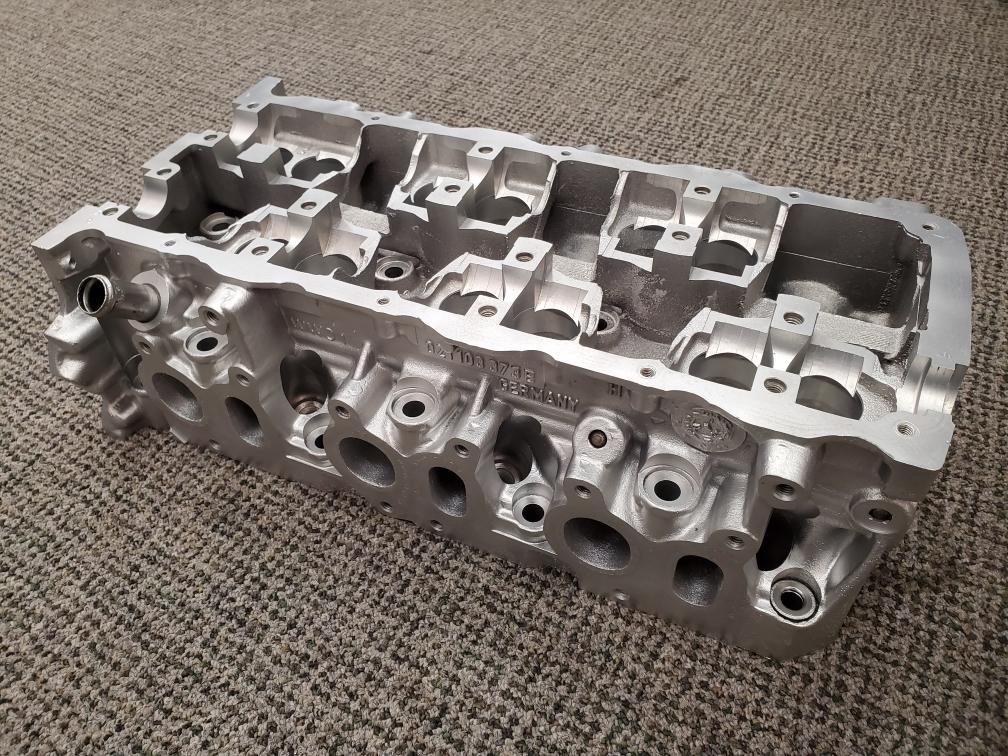

Unlike dry blasting where the finish is produced by sheer force of media impact, wetblasting does not allow for media to be impregnated into the component, nor is there any dust created by the break-up of media.

One of the main benefits of using a wetblasting process is that the media can be recycled. A specially designed glandless polyurethane pump agitates water and media into a slurry and pumps it to the blast gun. In order to accelerate the slurry to provide an excellent cleaning effect, compressed air is added to the blast nozzle.

Once contact has been made between the slurry and the component, the slurry is drained back into the sump creating a recirculating system. Broken down media is fed via an overflow to a sedimentation filter located at the rear of the cabinet.

Wet Blast Applications:

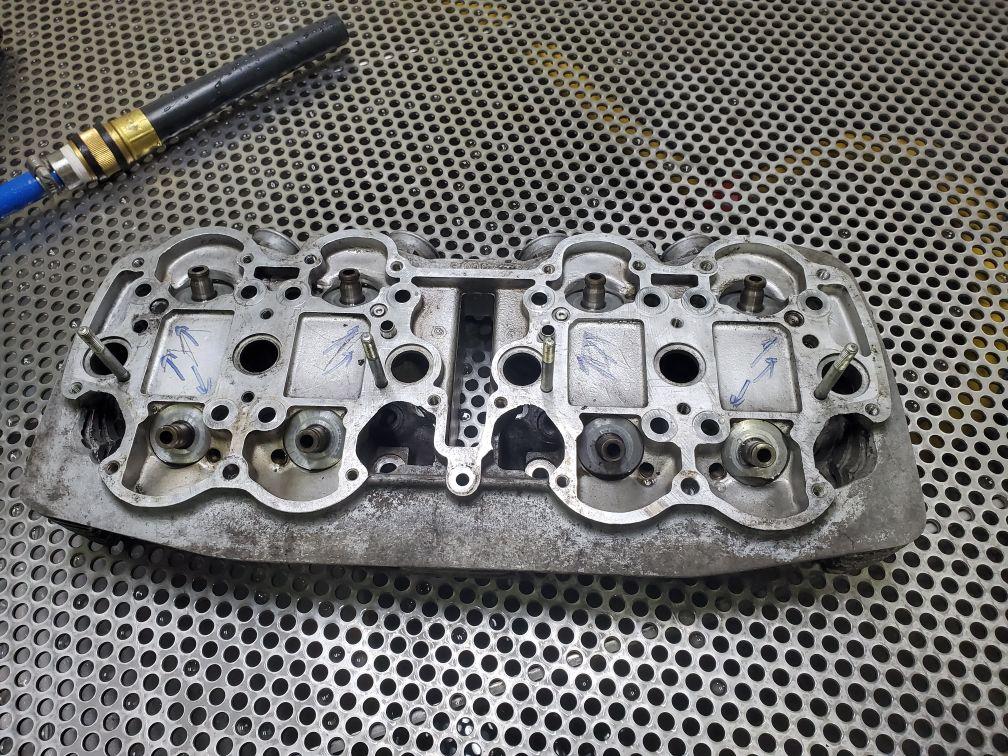

- Degreasing / surface finishing of components

- Cleaning of dies & moulds

- Removal of paint, rust, scale, carbon and similar deposits

- Surface preparation prior to bonding, re-painting or re-coating

- Satin finish of stainless steels, brass and other special materials

- Burr removal from machining marks

Wet Blast Applications:

- Automotive Restoration

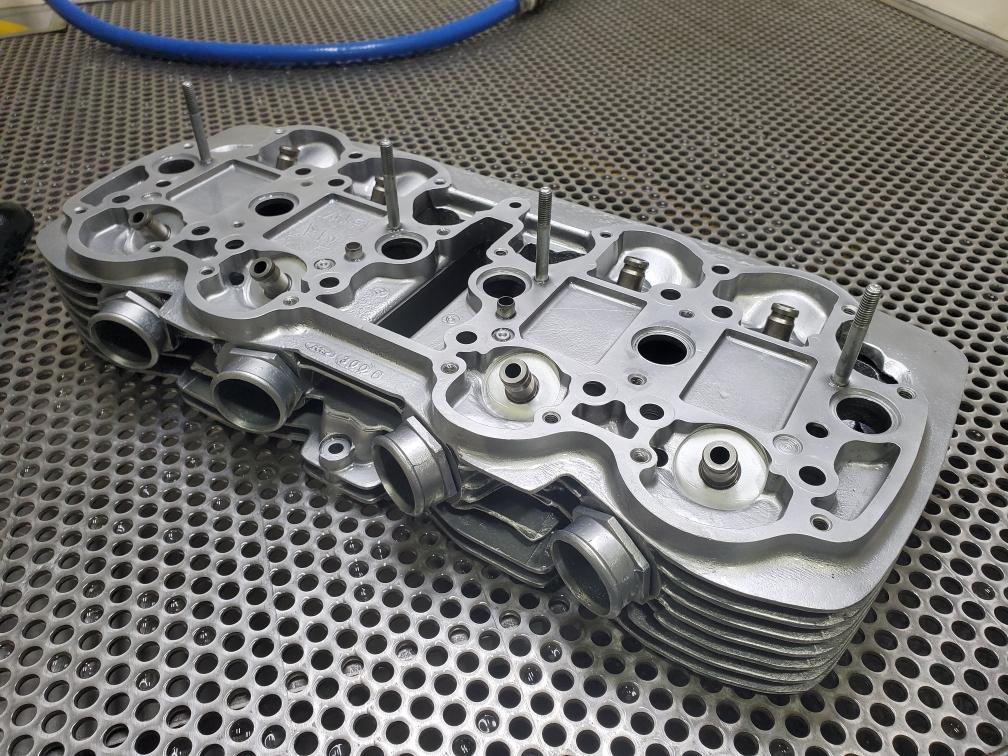

- Motorcycle Engine Parts

- High Performance Engine Building

- Automotive Part Remanufacturing

- Diesel Engine Rebuilding

- Deburring CNC Machined Parts

- Tool & Die

- Cutting Tools